The average human is comprised of somewhere between 55%-60% water. Earth itself? 71%. But even those substantial proportions can’t compare to the amount of water in most soft drinks—as much as 90%.

In many operations, soft drinks and other cold beverages are viewed simply as an add-on, but consumers, accustomed to the taste of their favorite beverages, expect a high level of consistency. When water quality is off, it’s a problem. Justin Thompson, president at the manufacturers’ rep firm YES Group, says, “Many soft-drink providers will increase syrup content at the dispenser head to mask [water] taste and odor.” That cover-up solution results in a slow profit leak in a high-margin category.

Water quality, in other words, impacts the customer experience and business results. Further, using unfiltered water can cause long-term damage to beverage equipment. Having the proper filtration equipment for cold beverage service is crucial.

Filtration First Steps

Foodservice operations rely on water filtration systems in many forms. (You can find our guide to outfitting a full facility, “H2O Care: Water Filtration Systems,” at fermag.com.) Here, we focus on selecting a filtration system for cold beverage dispensers.

Get a water quality report. To choose the right water filtration system, you need to know what kind of water you have in the first place. Water quality, both in terms of condition and taste, varies greatly by geography and other factors. Though it can have some limits, requesting a water quality report from your municipality is a necessary first step.

“That report will get you close,” says one manufacturer of water filtration systems. “It’s going to tell you what they are using to treat the water, and if they are using chlorine or chloramine as a disinfectant. Sometimes it will tell you the level of total dissolved solids, or TDS, and hardness level—but sometimes it doesn’t.” For a more comprehensive read of your water quality, you can have a third-party test it, and some water filtration companies will test it for free. Knowing the challenges in your water supply is critical information for choosing filtration equipment.

Get familiar with system features. Water filtration systems used in foodservice today typically take a two-pronged approach—removing excess particulates to prolong the life and performance of equipment and removing the unpleasant effects of chlorine or chloramine present in a public water supply. A typical set-up involves a system installed on the incoming water line itself, with filter cartridges designed to be replaced on a schedule determined by time and usage.

The physical (or “mechanical”) aspect of filtration equipment removes suspended particles by trapping various undesirable substances such as TDS. It also traps bacteria sometimes found in the water supply.

Carbon filters address issues of taste and smell. Off-flavors are commonly introduced by chlorine and chloramines, disinfectants used by most municipalities. While safe and necessary, these chemicals are detectable in beverages.

Calculate usage. The capacity needed in a water filtration system depends on how much water the beverage equipment uses. The capacity should be greater than the total amount of water that will be used between filter changes (typically every six months). Filtration products prominently display their recommended capacity, and consultation with a manufacturer can help you quickly find the right-sized system. Here is one basic formula for calculating usage:

- Add up the number of bag-in-boxes (BIB) used for all carbonated and noncarbonated beverages in a month and multiply times 25 (the number of gallons per BIB) to calculate monthly water usage.

- Estimate filtered drinking water dispensed from a post-mix valve or water fill station.

- Add together to calculate total monthly usage.

- Multiply total monthly water usage times six to calculate water usage over a six-month period.

For example, let’s say you use about 1,875 gal. of water a month via BIB and an estimated 500 gal. a month via drinking water; your equipment uses 14,250 gal. of water every six months. You’ll need a filtration system with a rated capacity of 15,000 gal.

On the Horizon

While the goals and even the methods of water filtration for cold beverages have remained the same in recent years, advances in technology continue to improve the process.

Filtration media has become more efficient, with pleated membranes that help provide protection from cysts (tiny microorganisms) and bacteria in the water supply. With minimal pressure drop (a problem with earlier generations of filtration), these filters now handle more sediment. The key is the higher surface area, compared with traditional precoated filters.

Manufacturers also have found a way to make carbon—a defense against the effects of chlorine and chloramines—more effective. “Carbon is still carbon, but now we can treat its surface area to target certain things,” says a manufacturer. “Standard carbon will take out chlorine, but chemically treated carbon material goes after chloramines at a better rate.”

Good Filtration

Keep up with customers expectations. These water filtration systems for cold beverage equipment will ensure a high level of taste consistency.

3M

MODEL: BEV140/BEV145

CAPACITY: 25,000 gal.

SPECIAL FEATURES: These single cartridge systems help improve the taste, appearance and consistency of your beverages. BEV140 combines cyst and bacteria reduction with particulate and chlorine taste and odor reduction; BEV145 combines particulate reduction with chlorine taste and odor reduction.

WEBSITE: 3Mfoodservice.com

Antunes

MODEL: VZN-541V

CAPACITY: 255,000 gal. (VZN-541VE carbon filter)

SPECIAL FEATURES: A self-cleaning ultrafilter ahead of a chlorine cartridge separates mechanical filtration from taste and odor reduction; this separation ensures a long time between cartridge changes.

WEBSITE: antunes.com

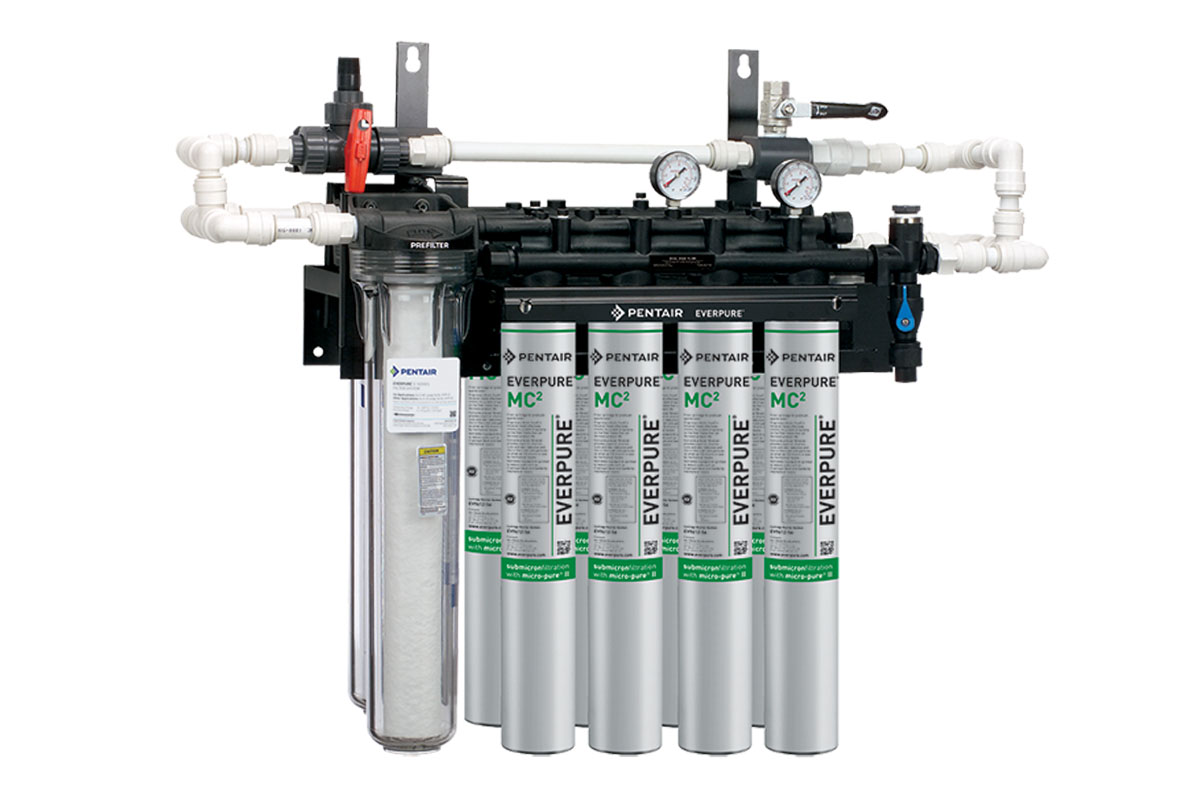

Pentair Everpure

MODEL: Dual High Flow Coldrink S-MC2: EV9337-44

CAPACITY: 72,000 gal.

SPECIAL FEATURES: High-volume central system delivers premium quality water to meet demanding peak periods; precoat filtration provides chlorine taste and odor reduction and microfilters dirt and particles by mechanical means.

WEBSITE: pentair.com

Pentair Everpure

MODEL: Dual High Flow Coldrink S-MC2: EV9337-44

CAPACITY: 72,000 gal.

SPECIAL FEATURES: High-volume central system delivers premium quality water to meet demanding peak periods; precoat filtration provides chlorine taste and odor reduction and microfilters dirt and particles by mechanical means.

WEBSITE: pentair.com

Antunes

MODEL: VZN-541V

CAPACITY: 255,000 gal. (VZN-541VE carbon filter)

SPECIAL FEATURES: A self-cleaning ultrafilter ahead of a chlorine cartridge separates mechanical filtration from taste and odor reduction; this separation ensures a long time between cartridge changes.

WEBSITE: antunes.com

3M

MODEL: BEV140/BEV145

CAPACITY: 25,000 gal.

SPECIAL FEATURES: These single cartridge systems help improve the taste, appearance and consistency of your beverages. BEV140 combines cyst and bacteria reduction with particulate and chlorine taste and odor reduction; BEV145 combines particulate reduction with chlorine taste and odor reduction.

WEBSITE: 3Mfoodservice.com

RELATED CONTENT

- Advertisement -

- Advertisement -

- Advertisement -

TRENDING NOW

- Advertisement -

- Advertisement -

- Advertisement -